Load building, also called Load planning, Load optimization, or Order Building is the set of processes aiming to optimize the use of truck capacity. More capacity in every truck means fewer trucks on the roads, decreasing pollution and saving money and the environment, so load building software improves sustainability.

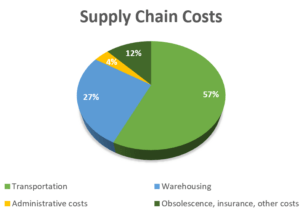

The majority of supply-chain cost is transportation. So, when looking for savings, transportation has the most significant leverage. Both supply and demand and fuel costs heavily drive transportation costs. Many sources claim that a shortage of truck drivers and equipment pushes prices higher.

First, AutoO2 makes the most effective pallets. It solves the problem by appointing pallets to trucks with strict packing constraints concerning axle weight, stability, and sequential loading, among other restrictions. Hence, it builds the largest possible damage-free load and integrates with any system.

In addition, AutoO2 creates optimization plans and provides instructions in 2D and 3D that warehouse workers may fully execute because the plans consider all possible elements, including minor details like pallets with overhangs.

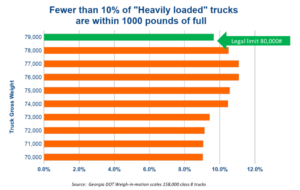

An analysis of trucks traveling across weigh-in-motion scales in Georgia shows that most trucks still need to be fully loaded. Therefore, it is the wasted capacity that load optimization software uses.

Why are trucks not full? Various reasons range from tribal knowledge of truck capacities being too small, the fear of over-weight fines, and lack of loader competence. But, by far, the biggest issue is most systems’ inability to build axle-legally stable, damage-free loads that use all the capacity, which AutoO2 knows how to solve.

As stated above, load building is the set of methods to optimize truck capacity. Truckload freight charges by the vehicle and more product on each truck mean reducing the freight cost per unit. Therefore, you ship fewer trucks over time with optimized load building.

Load planning builds legal solutions, increasing the cargo volume to the maximum possible, considering the product’s weight, stability, sequential loading, and demands for the products’ handling, such as stacking restrictions and transportation rules that govern axle weights in some countries’ axle positions.

Load building software creates the best possible solutions for the least-cost delivery of goods.

Applying optimal load building increases sustainability by reducing the number of trailers, landfill waste, and CO2 by increasing the payload volume and eliminating the possibility of damage. The more effective loads provide the economy and positively affect the environment.

Every product has parameters and dimensions, including stackability, which is a factor of case strength. Therefore, load optimization should build pallets such that the more substantial/ heavier cases are at the bottom of the pallet while weaker/lighter products are at the top.

Any load building software has many possible options, including the variables of trucks, carriers, trailers/ containers, and the number of trailers; the operators may add new ones manually, the same as the axle limits.

AutoO2, rather than using some crude measure like total weight or cube, optimizes load building using actual interior dimensions, axle placement, and more precise weight data of trailers/ containers and the tractors that pull them.

Additionally, each trailer type can be limited by availability.

Load optimization should be done using transportation methods: road, intermodal, rail, ship, or aircraft.

Prioritization is the ability of the load building to load items in the needed order.

Load building shows the results of optimization in 3D and 2D diagrams.

Ideally, load building software should integrate with any system (SAP, Kinaxis, OMP, DynaSys, BY, etc.) and any WMS to provide the load diagram to the loader. AutoO2 does.

Full integration with LevelLoad results in smooth transportation.