How hard is it to improve Supply Chain ESG? It is hard in some aspects, but the E may be improved significantly by enhancing existing planning systems with load building optimization software.

But first, let’s look at ESG.

ESG (Environmental, Social, and Governance) approach is becoming a new norm, morale, and best business practice. ESG is a set of standards the company uses.

Environmental in ESG means how a company protects the environment and includes corporate policies addressing climate change—social covers relationships with employees, suppliers, customers, and communities. Governance is for a company’s leadership, internal controls, and stakeholders’ rights.

The MIT Center for Supply Chain and Logistics study reinforced the importance of Supply Chain ESG.

David Correll, quoted in the Wall Street Journal, said, “One takeaway from [our survey] is that supply-chain sustainability seems to be here to stay, and it’s real.

Over three years of observation, every source of sustainability pressure that we monitor, for example, government regulations, customers, investors – has increased in perceived pressure.” So, in summary, the expectations are increasing.

Companies should take action now as the pressures and requests of society for ESG will continue to grow. Correll again: “Firms should take away from [the MIT survey] that what is enough now to impress your customers, your regulators or investors is not likely to be sufficient next year or for a different group of customers or regulators or investors.”

It’s a big task to maintain an efficient supply chain. Moreover, it is even more difficult to roll in all the supply chain ESG mandates.

There are many dimensions to ESG, but one that should be an easy and quick win is to focus on reducing the transportation carbon footprint. One easy way of doing this is to increase truck utilization. Simply put, most trucks traveling down the highway must be fully loaded.

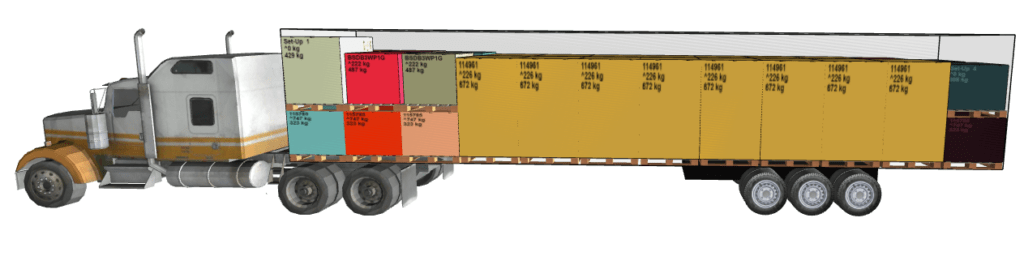

Integrating load building optimization AutoO₂ with the planning systems improves our customers’ E, takes the trucks from the roads, and decreases the company’s carbon footprint and landfill waste. But, it also reduces the transportation and whole supply chain costs, bringing an additional competitive edge.

Studies of shipments built by many major CPG companies show that by using an optimizing load builder like AutoO2 these companies can reduce 5 -10% of their shipments. It is an easy Supply chain ESG win.

But this is not just a Supply chain ESG win; it is also a win for the bottom line as freight costs are levied on the truck no matter how fully laden it is.

ESG (Environmental, Social, and Governance) approach is becoming a new norm and best business practice. For the supply chain, ESG revolves around “E” environmental –being green. And it’s easy to be green and save green (in the form of money) along the way. We’ll show you how.

There are many dimensions to ESG, but one that should be an easy and quick win is to focus on reducing the transportation carbon footprint.

One easy way of doing this is to increase truck utilization. Put more “stuff” on each truck. While most supply-chain managers would never deliberately create an order to underutilize truck capacity, the current simple load-building tools seldom achieve using more than 92% of a truck’s capacity.

Department of Transportation data shows most trucks traveling down the highway still have available capacity.

An optimizing load builder like AutoO2 can reduce 5 -10% of their shipments. And those shipments, in addition to being full, AutoO2 provides detailed loading instructions that minimize the potential for damage and ensure that the load arrives damage-free. It is an easy Supply chain ESG win.

But this is not just a Supply chain ESG win; it is also a win for the bottom line as freight costs are levied on the truck no matter how fully laden it is.

Companies like Unilever and Kimberly-Clark use AutoO2 to design deployment loads.

Integrating AutoO2 load-building optimization with their planning systems improves the E in ESG, takes the trucks off the roads, and decreases the company’s carbon footprint while cutting landfill waste.

Also, AutoO2 reduces transportation and whole supply chain costs while freeing up trucks, bringing innovative companies an additional competitive edge.