Most supply chain organizations measure costs, KPIs, and SLA performance. But one question remains surprisingly hard to answer:

Where are we actually losing value — and why? How to Identify Operational Losses in Supply Chains?

The answer isn’t found in financial summaries. It’s found in process deviations, upstream in the flow of work. Leading operations teams around the world use a process-first loss visibility framework that makes waste visible in real time, classifies it rigorously, and fixes it permanently.

Below is a practical guide you can apply to your own distribution, logistics, and operations teams — with examples, visuals, and references to tools and resources from ProvisionAI.

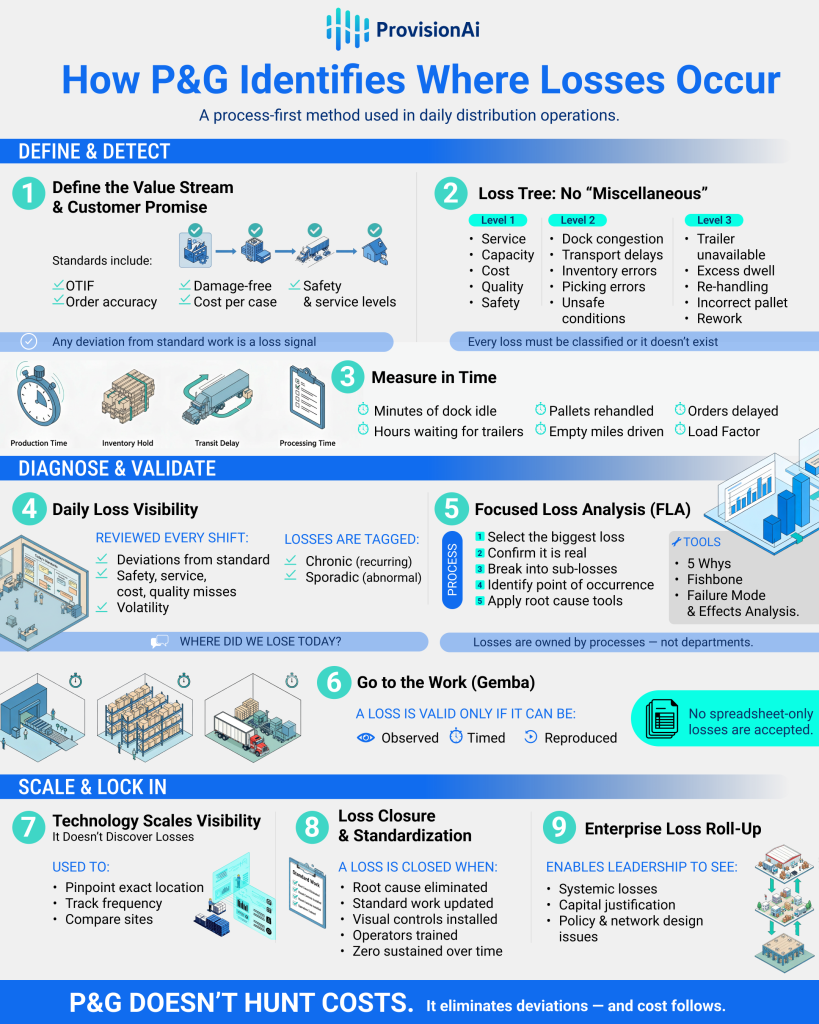

1. Define the Value Stream and the Customer Promise

Loss identification starts with clarity. The value stream must be defined end-to-end — from inbound production to final customer delivery — and tied to an agreed customer promise.

Core standards typically include:

- On-Time In-Full (OTIF)

- Order accuracy

- Damage-free handling

- Cost per case

- Safety and service levels

Key idea:

Any deviation from standard work is a loss signal.

If you haven’t agreed on standards, you have no baseline to detect losses.

2. Build a Loss Tree — No “Miscellaneous” Allowed

Vague loss categories hide real problems.

A loss tree breaks waste down from general to specific, such as:

Level 1: Service | Capacity | Cost | Quality | Safety

Level 2: Dock congestion | Transport delays | Inventory errors | Picking errors | Unsafe conditions

Level 3: Trailer unavailable | Excess dwell | Re-handling | Incorrect pallet | Rework

Operational rule:

If you cannot classify it, it does not count as a loss.

You can learn more about how structured loss classification dramatically improves accountability in this video:

👉 YouTube: Root Cause & Loss Visibility Framework

https://youtu.be/zRtw8uXnsgE

3. Measure Loss in Time — Not Just Dollars

Traditional cost reports capture what happened, but they tell you little about how or why it happened.

Instead, measure losses with time-based and physical indicators:

- Minutes of dock idle

- Hours waiting for trailers

- Pallets rehandled

- Empty miles driven

- Orders delayed

- Load factor gaps

Time-based measurements expose the actual process breakdowns, giving teams something real to act on.

ProvisionAI’s approach uses real execution data to measure exactly this — not just cost estimates.

📍 Watch this explanation here:

https://youtu.be/sCCh_4A_Nk8

You can also explore related short-form examples in this playlist:

Loss Measurement Shorts

https://youtube.com/playlist?list=PLyOtMLJjROxTS5emz2wt3eiKuGAqaO4_6

4. Make Loss Visibility a Daily Habit

Losses should be visible every shift, not just in monthly reports.

Teams with strong operational discipline review:

- Deviations from standard work

- Safety, service, cost, and quality misses

- Volatility and emerging patterns

- Whether losses are chronic (recurring) or sporadic (abnormal)

Daily visibility answers:

Where did we lose today?

If you only check variation monthly, it’s already too late.

5. Analyze the Biggest Loss First

Once a loss is visible, prioritize and analyze it using a structured root-cause method:

- Select the biggest loss

- Confirm it is real

- Break it into sub-losses

- Identify where it occurred

- Apply root-cause tools (5 Whys, Fishbone, FMEA)

This is not departmental — it’s process ownership.

Losses don’t belong to teams, they belong to processes.

6. Go to the Work (Gemba)

A loss is only valid if it can be:

- Observed

- Timed

- Reproduced

If a loss only exists in a spreadsheet or dashboard, it isn’t operational — it’s theoretical.

Equip your team to validate losses on the floor, at docks, in yards, or during handoffs, with hard observations.

No spreadsheet-only losses are accepted.

This principle is core to ProvisionAI’s methodology and embedded in our platform’s workflows, tying system data to real execution.

7. Use Technology to Scale Visibility

Technology doesn’t discover losses — it scales visibility and tracking.

Systems should be used to:

- Pinpoint exact loss location

- Track frequency over time

- Compare across sites and shifts

But without strong process definitions, tools merely report outcomes — they don’t explain causes.

ProvisionAI’s software aligns technology with operational context so that:

✔ visual patterns lead to insight

✔ anomalies highlight real issues

✔ leadership sees trends, not just numbers

8. Close the Loss and Standardize the Fix

A loss is only closed when:

- The root cause is eliminated

- Standard work is updated

- Visual controls are installed

- Operators are trained

- Zero is sustained over time

If a loss comes back, it was never truly solved.

This reinforces discipline and creates a learning organization out of everyday execution.

More on this concept here:

🔗 Operational Excellence Resources

https://provisionai.com/resources

9. Roll Losses Up to the Enterprise Level

Once loss data is consistent and structured across sites, leadership gains visibility into:

- Systemic loss drivers

- Capital investment needs

- Policy and network design issues

This bridges operational execution with strategic decision-making, turning frontline data into enterprise insight.

Bringing It All Together | How to Identify Operational Losses in Supply Chains

Most organizations:

- Chase cost numbers

- Wait for monthly summaries

- Rely on dashboards that don’t tell the story

High-performing teams take the opposite approach:

- Make losses visible in the process

- Standardize how they are measured

- Analyze and fix them at the source

Eliminate deviations first. Cost improvements will follow.

At ProvisionAI, we help operations teams measure execution in real time, connect it to loss classification frameworks, and build bulletproof process visibility across networks.

📺 Recommended Videos to Embed or Link

- Core Framework Explained: https://youtu.be/zRtw8uXnsgE

- Measuring Loss in Time: https://youtu.be/sCCh_4A_Nk8