The article by Keith Moore, “Smooth Operator – New Tools Enhancing Fulfillment Optimization,” (December 26, 2023) for Inside Logistics, explores the challenges in order fulfillment within supply chains.

In the vast realm of supply chain concerns, order fulfillment takes center stage, demanding precision in delivering the right products to the right places at the right times. Keith Moore, CEO of AutoScheduler.AI, sheds light on the challenges faced during the execution phase, emphasizing the critical role of seamless operations.

Executing supply chain plans is no cakewalk. Challenges encompass truck availability, warehouse space management, and ensuring ample labor for order processing. The execution phase becomes the litmus test for even the most meticulous planning teams.

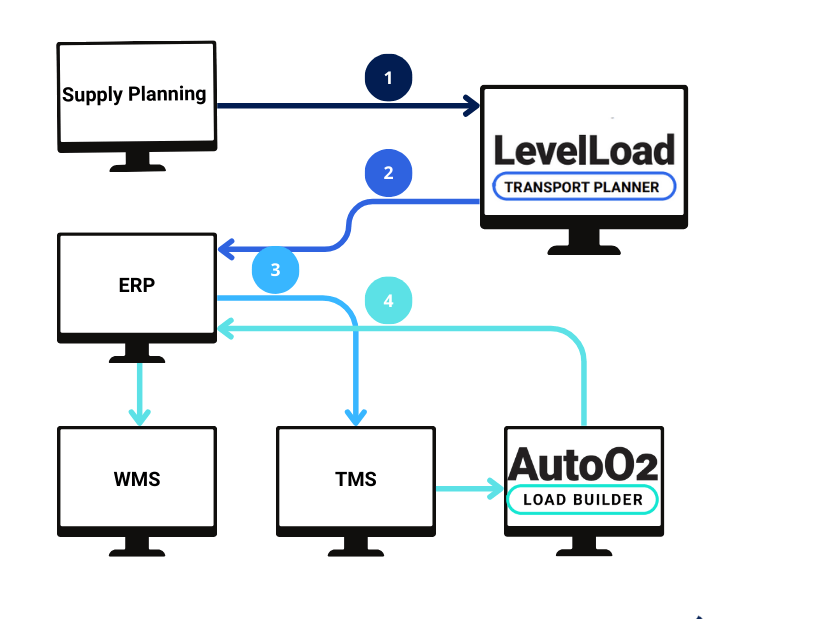

Fortunately, a new wave of optimization technologies is surfacing, bridging the gap between planning and execution. These tools promise to facilitate the smooth inventory flow from manufacturing to customers, irrespective of the sales channel. The key lies in advanced optimization techniques that streamline transportation plans, maximize truck capacities, and ensure on-time deliveries.

In the realm of deployment planning, these solutions employ constraint-based mathematics. The aim is to balance minimizing costs and maintaining optimal inventory levels.

Load optimization extends benefits beyond cost reduction. Maximizing truck capacity translates to significant fuel, labor, and maintenance savings. Fewer trucks mean reduced fuel consumption and emissions, aligning with sustainability goals. Optimized loads also result in more accurate delivery windows, reducing the chances of delays and enhancing customer satisfaction.

After transportation planning, the focus shifts to distribution sites. Scheduling solutions come into play, offering intelligent warehouse orchestration. These tools provide a holistic view of inventory, labor, equipment, and customer shipments, aiming to streamline inventory flow and ensure timely dispatch.

What sets these tools apart is their utilization of mathematical optimization. They process myriad constraints to reduce costs and boost throughput, addressing factors like equipment capacities, shift schedules, and space availability. In dynamic warehouse environments, these tools bring predictability, analyzing real-time data to forecast potential bottlenecks.

Advanced optimization tools offer transparency across the entire supply chain. Stakeholders, from floor workers to executives, gain a clear understanding of how execution will unfold. This visibility ensures smoother operations and instills confidence by proactively addressing challenges.

Bolt-on tools, seamlessly integrating with traditional software solutions, emerge as game-changers in order fulfillment. They offer innovative solutions without requiring a complete system overhaul. Instead of disruptive changes, these tools enhance existing infrastructures, allowing supply chains to operate efficiently.

These tools represent the future of supply chain management, where innovation meets practicality. Rather than costly and time-consuming “rip and replace” strategies, these bolt-on tools enable companies to leverage existing investments while embracing modern optimization for unparalleled results. Keith Moore concludes that they signify a future where innovation and practicality converge to redefine supply chain efficiency.